This week I have been fixing a persistent problem that has been bugging the layout for around the last twelve months.

When I originally did the track work for the layout I used a combination of PECO Code 83 track & turnouts and Walther's Shinohara Code 83 turnouts. The build quality between the two is quite obvious when comparing the two.

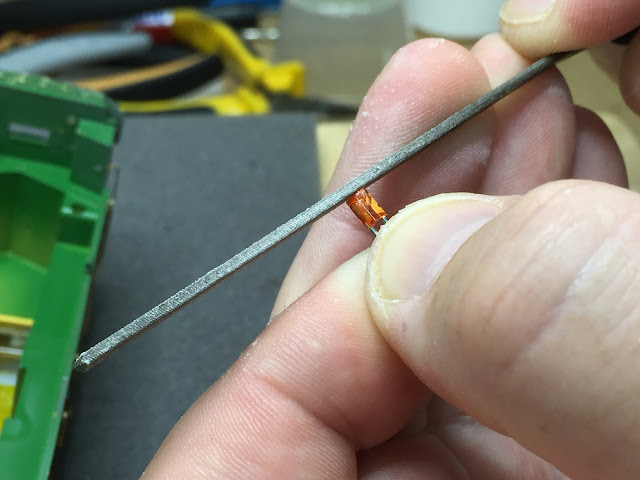

For the first three to four years the Shinohara turnouts have been fine. I had to adjust a couple of the point ends on a couple but apart from that there were no issues. But over the last twelve months they have required regular maintenance and tweaking to keep the point closed against the rail even under Tortoise switch machine tension.

After our last ops session it was also noted that several of the turnouts were in fact out of gauge by at least 1 - 2mm on several of them. So I have decided to replace them all with PECO - Code 83 #7 LH & RH Curved Turnouts.

This has also allowed me to do another turnout & crossover justification for the existing track work. As the original operating plan and track work has changed since going down the switching layout path I have removed several turnouts & crossovers too.

First job was to remove the crossover coming into Rutherford. As there is a crossover in Rutherford itself the Shinohara crossover was removed and replaced with track only...

On the other side of the backdrop (to the left of photo) was another two Walthers - Shinohara Turnouts, these have also been removed...

The top set of Shinohara turnouts (crossover) was a constant source of maintenance & tweaking throughout the year.

With the removal of the turnouts coming into Harrisburg this required a chance to clean up and realign the track work and turnouts. The photo below shows the newly installed PECO #7 Curved turnout coming into a #8 RH turnout which is also Code 83 PECO too.

When looking from the other direction the flow of track has been improved greatly and it has also removed the excess curve that was there from using the original Shinohara turnouts as can be seen by the existing cork road bed to the right of the track.

To finish off I also removed a slight hump that existed from the mainline coming from Carlisle Junction (from the left) to the right into Rutherford right underneath the backdrop, the transition is now a perfect grade into level with no more hump.

Next step is to work my way around the remainder of the layout and replace all of the Shinohara turnouts.

Jas...