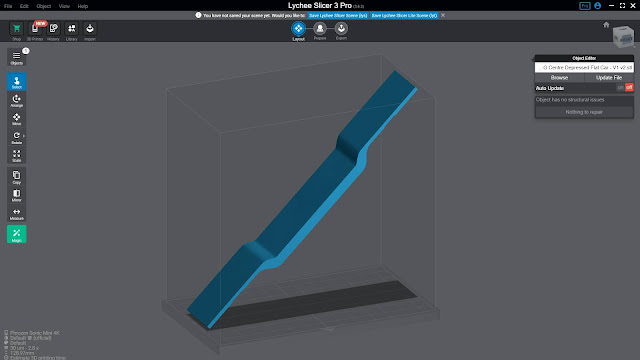

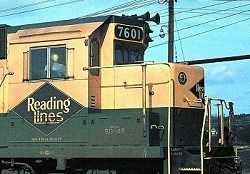

Ok I’m calling the design & the first complete prototype of the Reading (RDG) - FWd Depressed Centre Flatcar (HO Scale) done.

I’ve checked everything today, finalised the design, and printed the pin system to secure the trucks & couplers to the flatcar body.

I’ve settled on the print settings for the Sonic Mini 8K & the support placement that has produced an impressive print today. I still have to print successive & successful prints without failures too.

I’m working with Highball Graphics to also produce a decal set for the RDG units. Once I’ve achieved consistent prints, with the quality I’ve produced today & the decal sets are ready, I’ll put them up for sale online.

The kits are going to be offered as an undecorated kit, with the main flatcar section, trucks, Kadee Narrow Coupler boxes & securing pins. I’ll list the other parts I’ve used (wheelsets & couplers) but leave the final choice & purchase to the buyer.

I’m aiming the quality & therefore price point somewhere between a Bluebox & RTR type model. As these haven’t been on the market, and resin is somewhat untested in the hobby, the price will be reflective of this.

Jason.